Motor control center products play an extremely important role in industrial production, integrating various motor control and process monitoring equipment. In traditional MCC product applications, the control system mainly transmits information to MCC through hard wiring, which is very complex and the amount of information transmitted is relatively small.

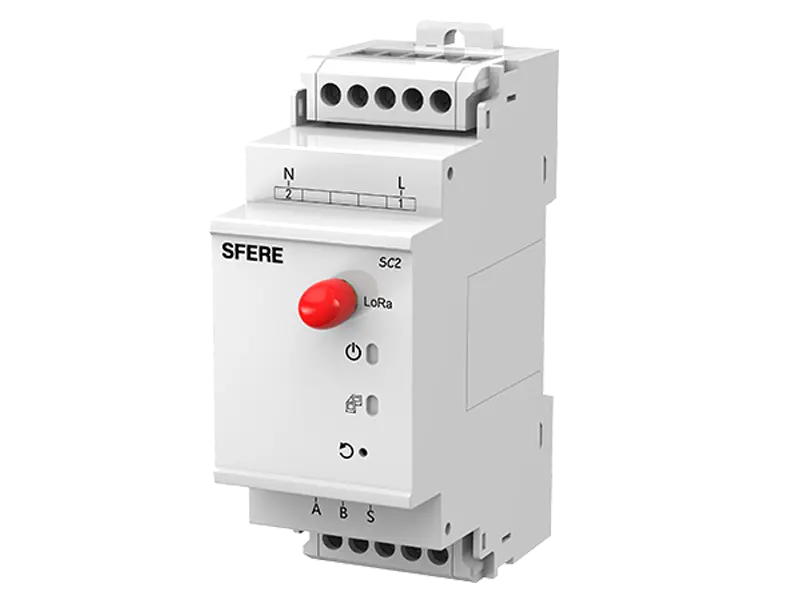

With the development of network technology and intelligent devices, a new type of intelligent motor control center (iMCC) has emerged, which tightly integrates hardware, software, and network together.

Its characteristics are:

(1) Equipped with built-in communication network;

(2) Each unit contains intelligent devices with network communication functions;

(3) Contains MCC specific monitoring software;

(4) Communicate information with the control system through a network rather than hard wiring.

Intelligent motor control center

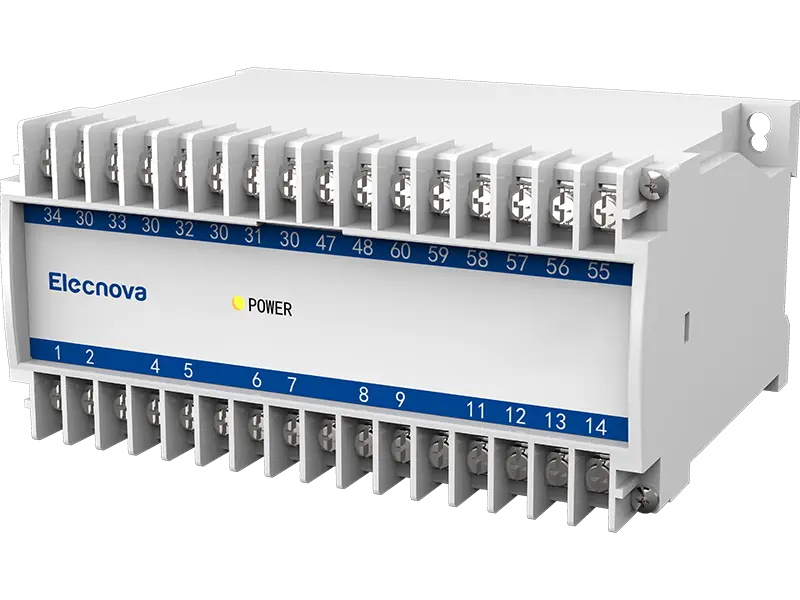

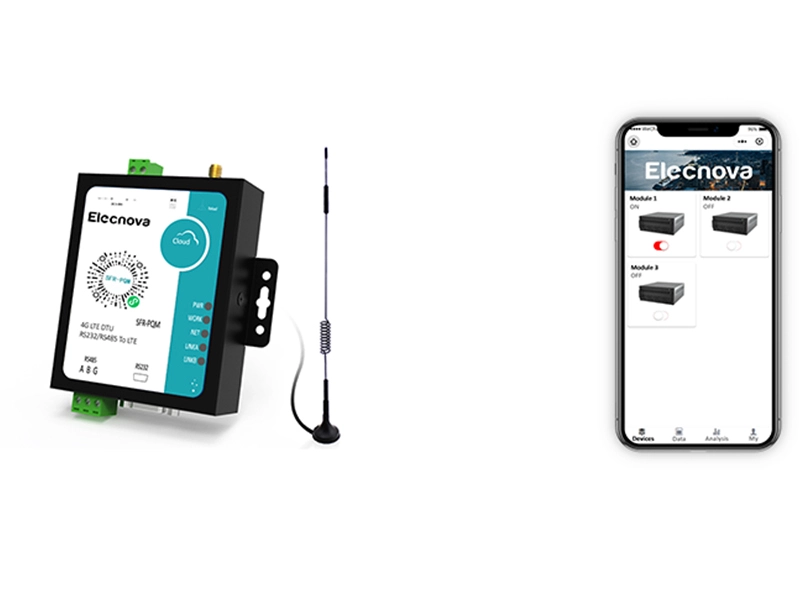

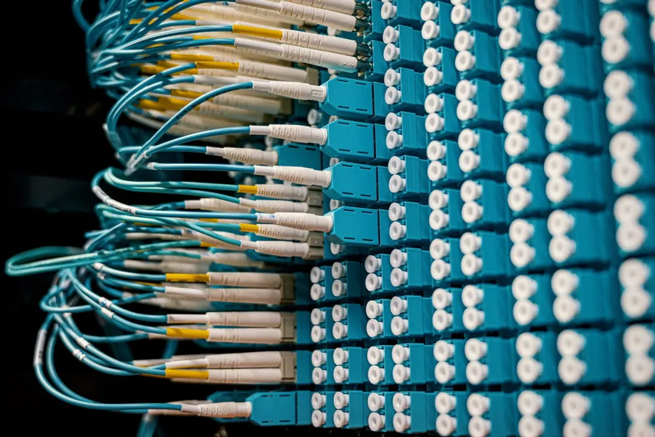

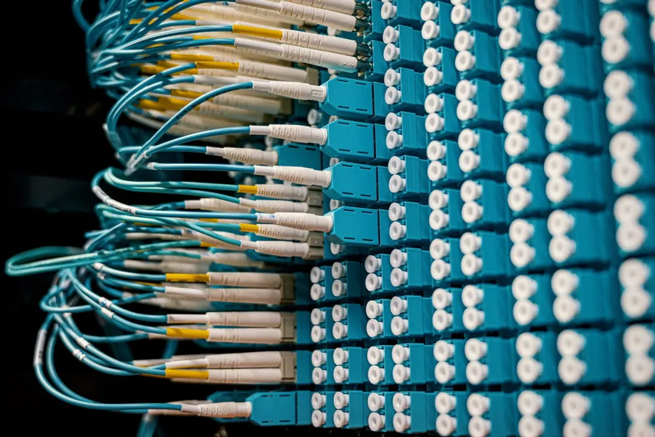

1 Communication network

A communication network can be formed through communication methods such as RS485 and Ethernet, and the entire communication network has the following characteristics:

(1) Reduce faults caused by control terminals.

(2) Reduce the I/O volume of the PLC system, including switching and analog quantities.

(3) Reduce the cost of control cables, corresponding construction materials, and labor.

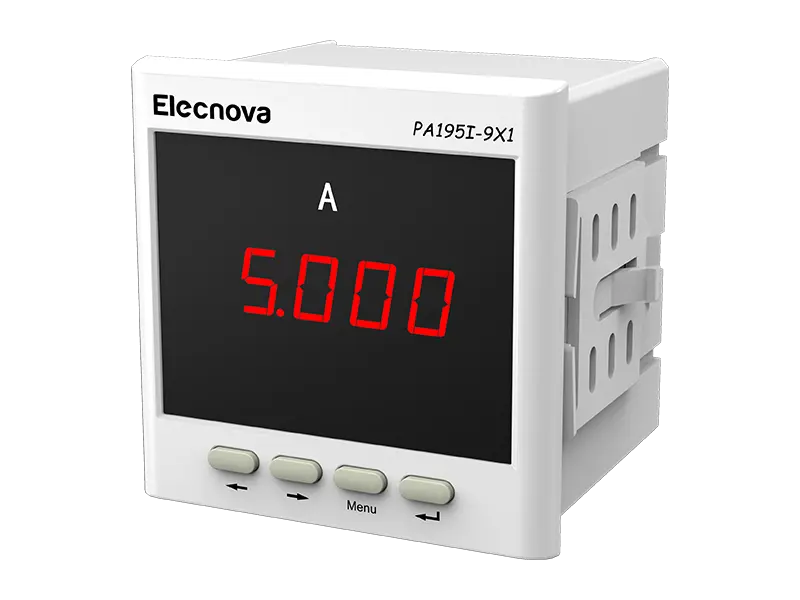

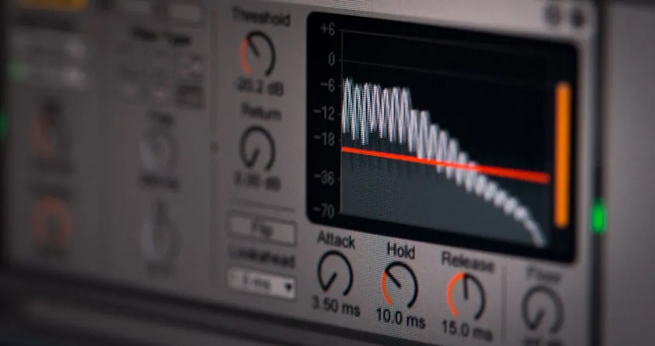

2 intelligent motor protectors

The intelligent motor protector, as the core component of MCC, provides the following main functions:

(1) Enhanced protection function greatly surpasses ordinary overload relays.

(2) Including zero sequence grounding fault, PTC thermistor input and overload, phase loss, locked rotor, current imbalance protection, etc. All protections are set digitally, accurately and reliably, while providing alarm and trip functions.

(3) Alarm setting provides pre alarm: provides pre maintenance function to know the fault content in advance.

(4) Built in Modbus RTU, Profibus DP, DeviceNet and other communication interfaces: All controls no longer require external PLC I/O modules.

(5) Provide multiple switch input and output points: used to collect the status of contactors and circuit breakers and control the action of contactors.

(6) Internal storage usage information: Provides useful preventive information for user production, including trip warning time, reset time, thermal capacity percentage, recent multiple alarms and trip reason records, as well as other measurement parameters.

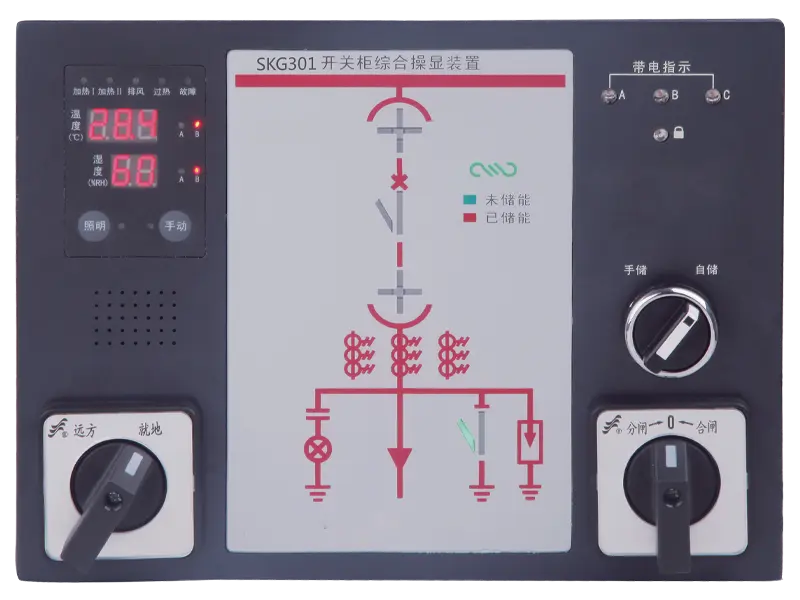

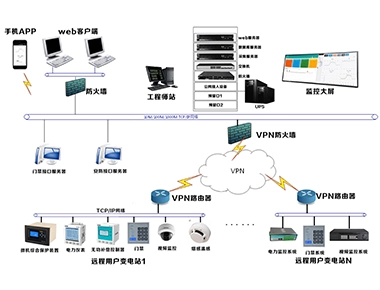

3 iMCC monitoring software

The intelligent iMCC is equipped with dedicated software to detect various data and status of the iMCC.

The following points provide the basic characteristics of typical intelligent motor control center software:

(1) Starting network communication - configuring and building an integrated communication network is often a very time-consuming task. However, ideally, iMCC manufacturers would download user specific information (custom or standard drawings), such as node addresses and baud rates, to iMCC products and then test the functionality and communication accuracy of the entire system.

(2) Display pre configured screens and provide the most common parameters: intelligent iMCC software can extract user-defined data files, display relevant screens, and predefined software screens are very helpful.

(3) Cabinet layout diagram: Provide an actual layout diagram of the iMCC cabinet, displaying unit type, status, and various information.

(4) Detailed information diagram of the specified circuit: Provide various information of the corresponding circuit.

(5) Data access can be conducted on any level of network, and users can access iMCC data on any level of network, such as device network, control network, or Ethernet.

(6) Contains all user related documents: The comprehensive document library software provides a complete set of documents to minimize the possibility of missing component manuals when faults occur. These documents include: ① Unit wiring diagrams; ② IMCC cabinet layout diagram; ③ Product User Manual; ④ List of spare parts.

4 Cost estimation

Intelligent iMCC uses communication network cables to replace various hard wiring. Compared to traditional MCC, the cost of intelligent iMCC is basically the same. However, the benefits that intelligent iMCC communication networking brings to users are obvious. The flexibility of unit movement has been enhanced, simplifying system wiring and documentation. Moreover, the use of new intelligent components such as intelligent motor protectors, AC frequency converters, soft starters, etc., at a relatively low cost, can provide many advanced control, monitoring, and diagnostic functions, bringing greater economic benefits to customers.

Therefore, intelligent iMCC solutions are increasingly becoming the preferred choice for many important applications in industries such as petrochemicals, metallurgy, cement, and papermaking.

5 Advantages Analysis

Intelligent iMCC has achieved significant cost savings by reducing design, installation, and documentation time. The reason for saving funds is that the demand for cables is greatly reduced, including cable supports and interface equipment, such as terminal boxes, control system I/O modules, and plug-in relays.

In fact, compared to traditional MCC installation, the installation cost reported by intelligent iMCC users has been reduced by 15%. Users can achieve additional cost savings by improving diagnosis, which helps with faster troubleshooting.

Without intelligent motor control, pre configured iMCC software, and a network architecture that allows technicians to collect data and configure devices, engineers will be forced to use trial and error methods. With all these features, engineers spent a few minutes solving each problem instead of a few hours.