Power Distribution Unit (PDU) monitoring involves the continuous tracking and analysis of electrical parameters and operational status of PDUs used in data centers, server rooms, and other critical facilities. PDU monitoring provides valuable insights into power usage, efficiency, and reliability, helping optimize energy usage, prevent downtime, and ensure operational continuity. Here's how PDU monitoring works and its key benefits:

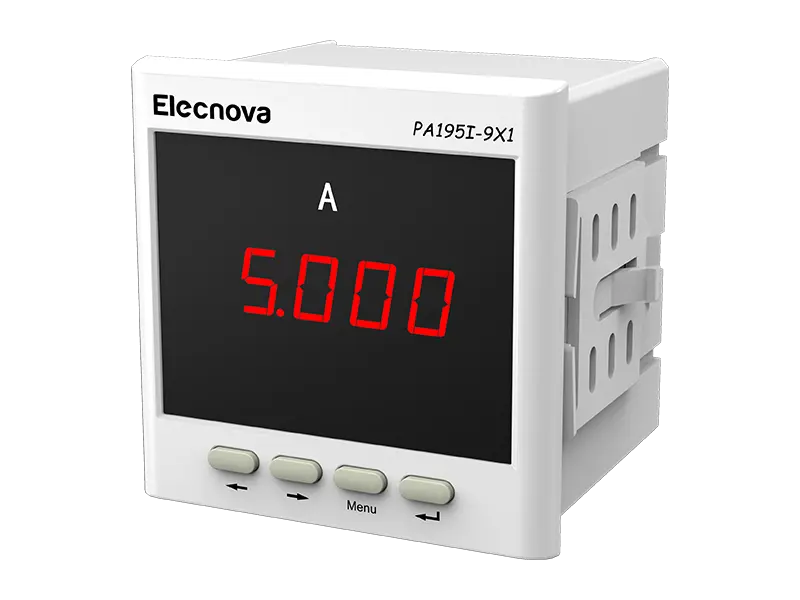

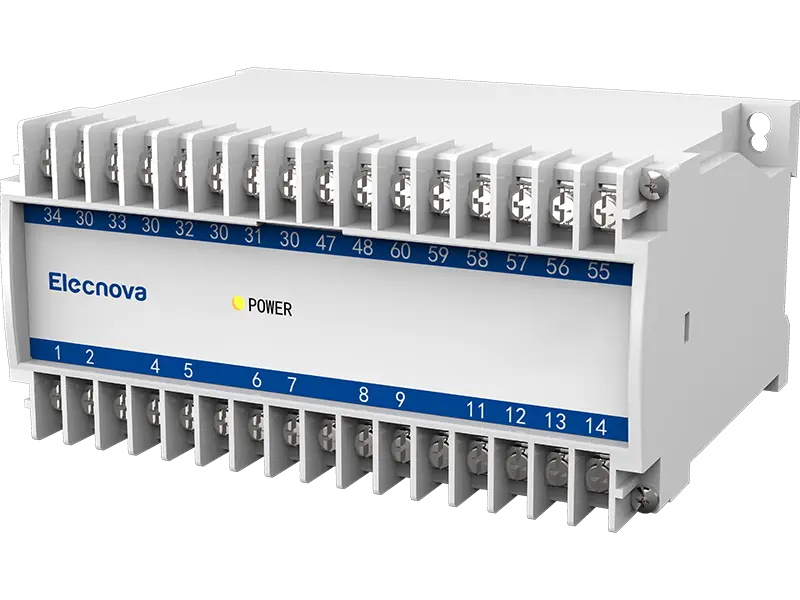

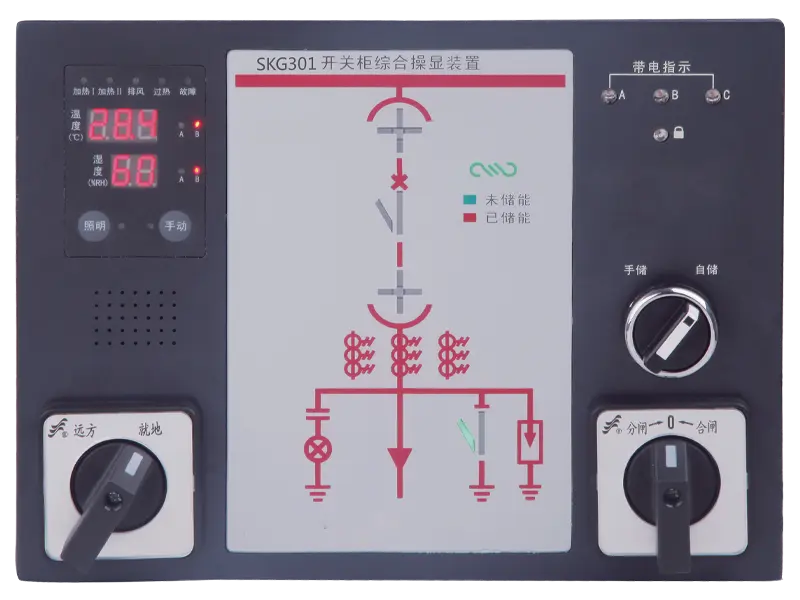

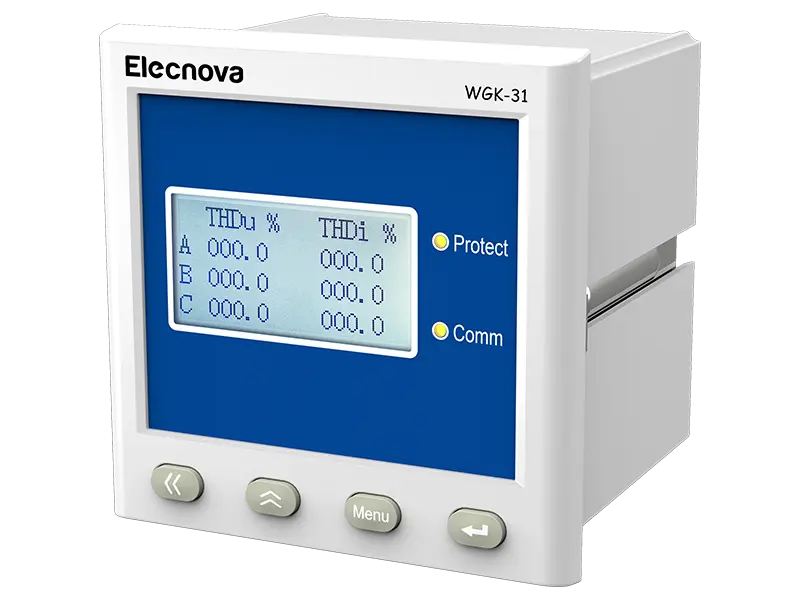

1. Real-time Monitoring: PDU monitoring systems continuously collect data on electrical parameters such as voltage, current, power, and energy consumption from individual PDUs. Real-time monitoring allows operators to promptly identify abnormal conditions, such as overloads or voltage fluctuations, and take corrective actions to prevent equipment damage or downtime.

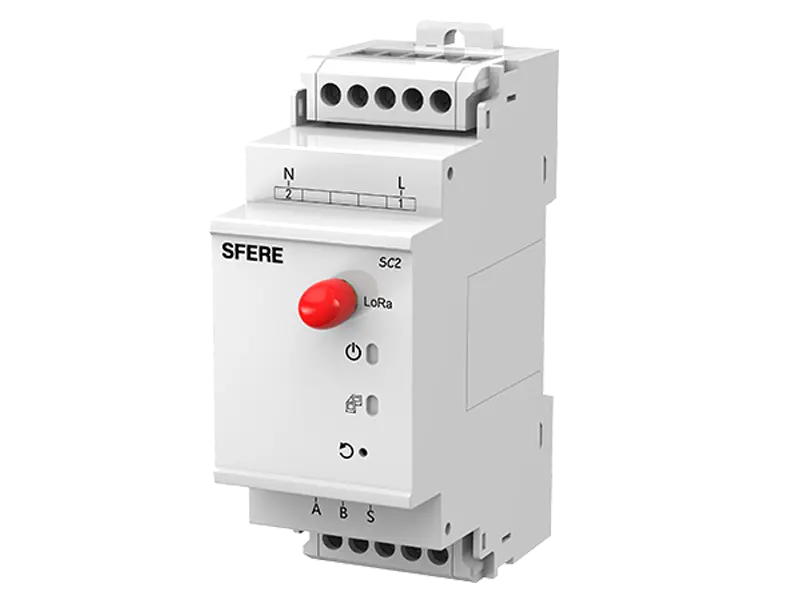

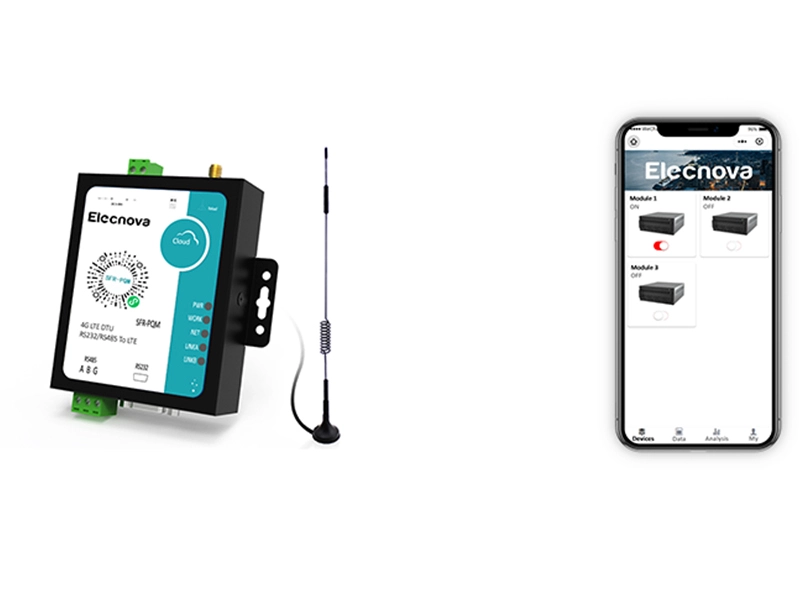

2. Remote Access: PDU monitoring systems typically offer remote access capabilities, enabling administrators to monitor and manage PDUs from anywhere with an internet connection. Remote access facilitates quick response to alarms or alerts, reduces the need for on-site visits, and enhances operational efficiency.

3. Data Analysis and Reporting: PDU monitoring systems analyze collected data to identify usage patterns, trends, and potential issues. Administrators can generate reports on power usage, load balancing, and equipment health to support informed decision-making, capacity planning, and compliance with regulatory requirements.

4. Energy Efficiency: PDU monitoring helps optimize energy usage and improve efficiency by identifying areas of power wastage or inefficiency. By monitoring power usage at the PDU level, administrators can implement energy-saving measures such as load shedding, equipment consolidation, or equipment upgrades to reduce energy costs and environmental impact.

5. Capacity Planning: PDU monitoring systems provide insights into power usage trends and capacity utilization, enabling proactive capacity planning and resource allocation. Administrators can identify underutilized or overloaded circuits, redistribute loads, and plan for future expansion or upgrades to ensure sufficient power capacity and avoid costly downtime.

6. Fault Detection and Prevention: PDU monitoring systems detect faults, anomalies, or deviations from normal operating conditions, such as circuit failures or phase imbalances, and generate alerts or notifications. Early detection of potential issues allows administrators to take preventive measures, schedule maintenance, or replace faulty components before they escalate into critical problems.

In summary, PDU monitoring plays a vital role in ensuring the reliable and efficient operation of electrical infrastructure in data centers and critical facilities. By providing real-time insights, remote access, data analysis, and proactive management capabilities, PDU monitoring helps optimize energy usage, enhance reliability, and minimize downtime, ultimately contributing to the overall performance and success of the facility.