- Smart Meter

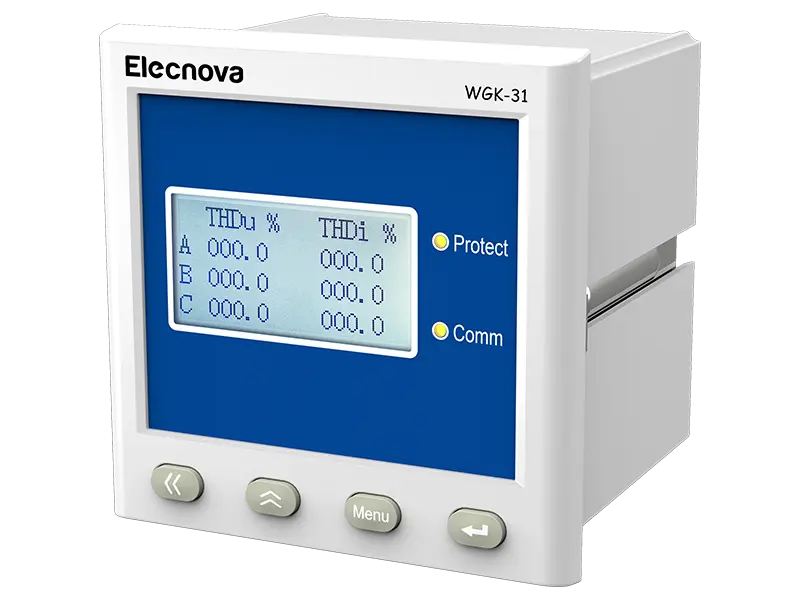

- Multi-Functional Power Meter

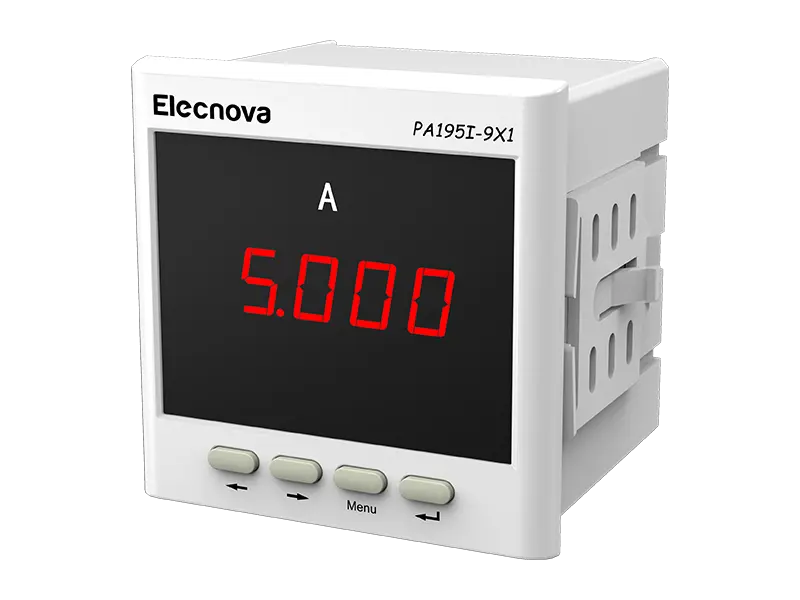

- Digital Power Meter

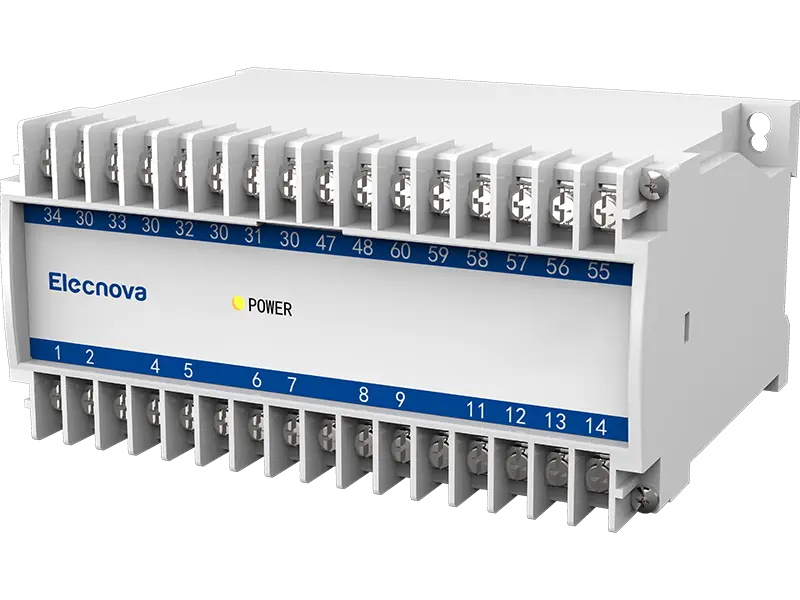

- Intelligent Electrical Transducer

- Multi-circuit Monitoring Unit

- Multi-Circuit Power Meter

- Precision Power Distribution Unit

- Motor Protection Controller

- Microcomputer Integrated Protection Device

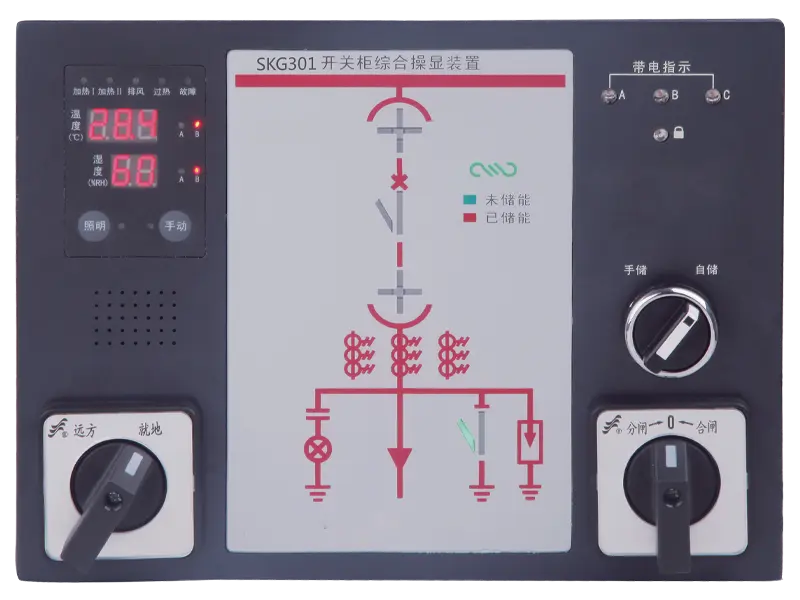

- Intelligent Control Device for Switch Cabinet

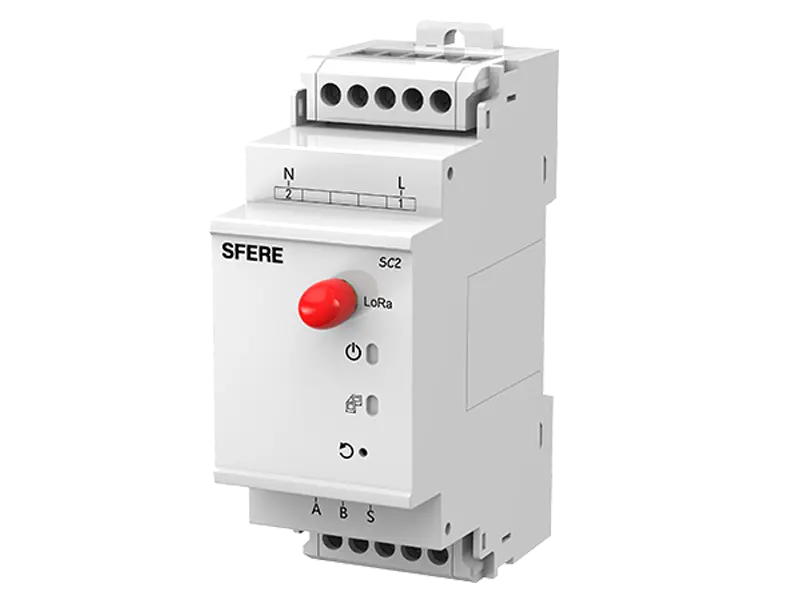

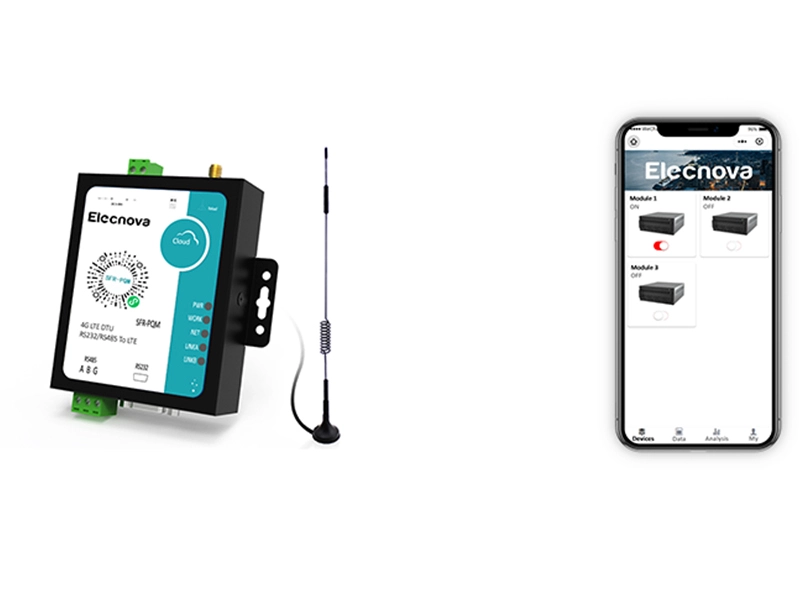

- Communication Gateway

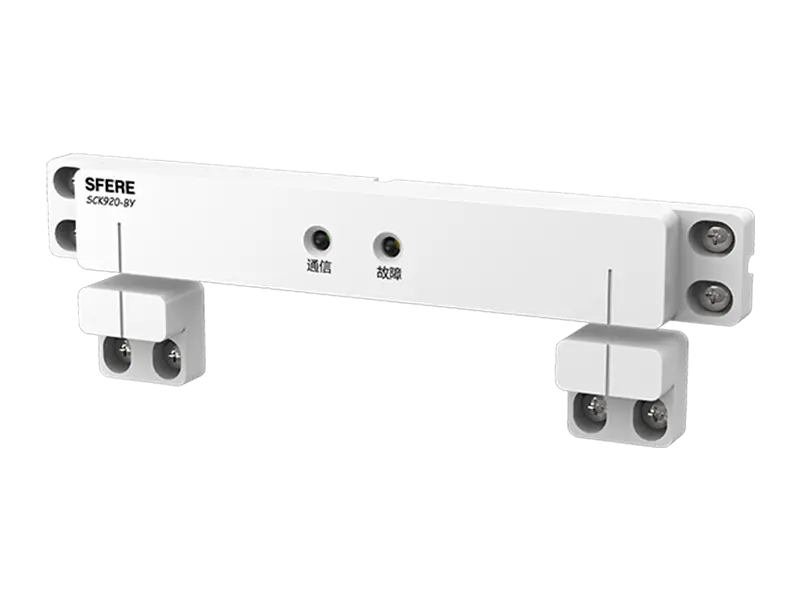

- Rack-Mounted Busway Monitoring Unit

- Current Transformer

- Integrated Multi-functional Power Meter

- Active Harmonic Filter (APF)

- Static Var Generator (SVG)

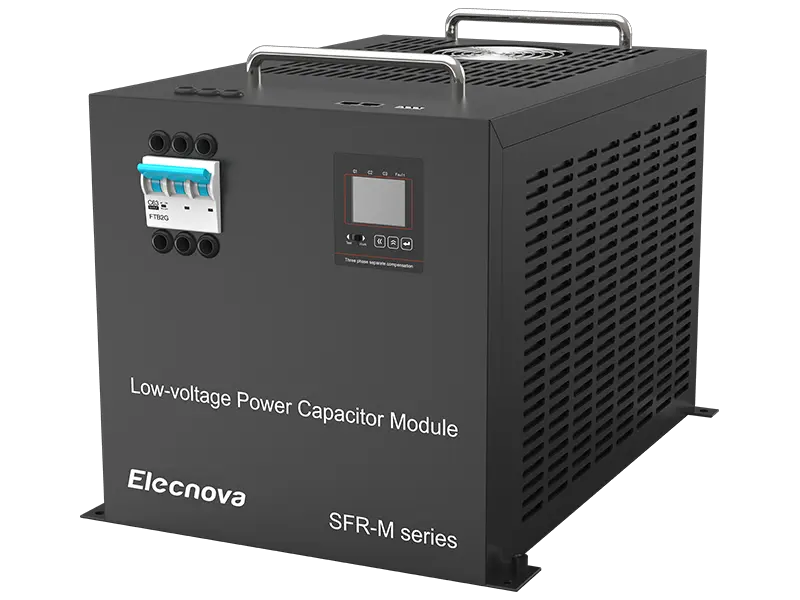

- Smart Capacitor Bank

- Harmonic Mitigation & Reactive Compensation Component

- Switch & Control Unit

- Intelligent Power Quality Management Software

- Power Quality Monitoring Cabinet

- Intelligent Measuring Terminal for Electrical Safety

- Electrical Fire Monitoring System

- Fire Fighting Equipment Power Monitoring System

- Fire Door Monitoring System

- Temperature Monitoring System

- Surge Protection Device

English

What are you looking for?