With the acceleration of 5G large-scale commercial and fixed-line users, the corresponding landing of 5G various application scenarios will lead to an exponential increase in the type and quantity of data, and the demand for data centers will reach an unprecedented level. The construction of IDC (Internet Data Center) computer room supporting power supply plays a key role in the development of the data center. At present, the uninterruptible AC power supply system (UPS) is widely used in IDC machine room, but at the same time, more and more projects adopt the 240 V high-voltage DC power supply scheme. The 240 V high-voltage DC power supply system is mainly composed of rectifier cabinet, DC cabinet, battery, DC distribution cabinet and column head cabinet. Compared with UPS power supply system, high-voltage DC power supply system has the advantages of less conversion links, high efficiency, high reliability, convenient maintenance and long service life.

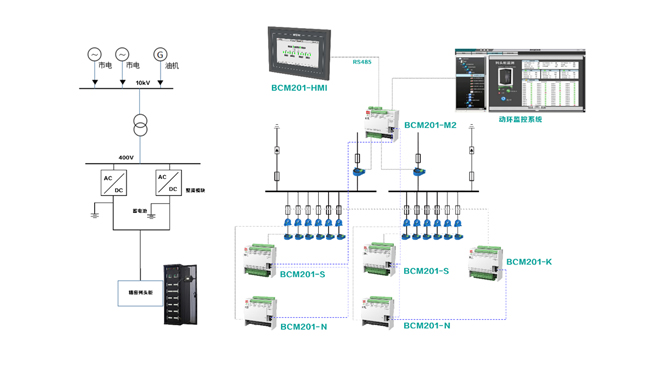

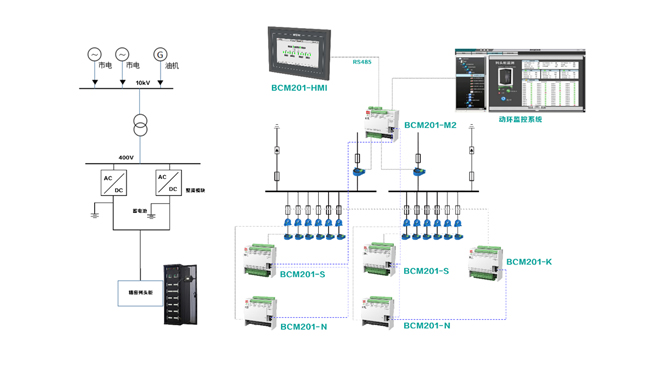

The Sfere BCM201 high-voltage DC precise power distribution monitoring unit can achieve high-precision power monitoring for each circuit in the DC array cabinet, and achieve refined energy consumption management. At the same time, the insulation monitoring module can monitor the insulation performance of the entire DC system to the ground. The DC precise power distribution single metadata can be uploaded to the dynamic monitoring system through digital communication, providing reliable guarantee for operation management.

Sfere BCM201 DC Precise Power Distribution Monitoring Unit

Function Feature

Modular design, easy extension

Colorful LCD local display with flexible interface customization

Bus connection between modules, integrated communication and power supply

Measurement of total electrical quantity of incoming and feeder circuits (including switch quantities)

Two RS485 communication interfaces and one Ethernet interface

Monitoring Function

Real time display of incoming circuit power data

Real time monitoring of the basic data of the incoming circuit, including voltage, current, power, and electrical energy data.

Real time display of power consumption data for each circuit of the line

Real time monitoring of basic electrical data for each feeder circuit, including voltage, current, power, and other data.

Real time monitoring of the switch status of each circuit

Real time monitoring of the switch status of each circuit through BCM201-S can display real-time closing, opening, alarm, and not enabled.

Real time alarm display

Real time display of alarm information, including alarm time, alarm value, and other information, to quickly guide operation and maintenance personnel to handle faults in a timely manner.

Operation record query

Query the alarm records for exceeding the battery limit and display historical alarm information; Record in detail the alarm battery level, alarm type, and alarm start time; By querying historical events, the status of the running line during the alarm can be traced.

Real time monitoring of dynamic environment monitoring system

Real time monitoring of energy consumption and alarm status of each circuit facilitates customer operation and analysis. The local system adopts a 7-inch or 10 inch human-machine interface, which is convenient for interactive operation and provides an Ethernet interface to connect with the superior monitoring system.

Component parameters

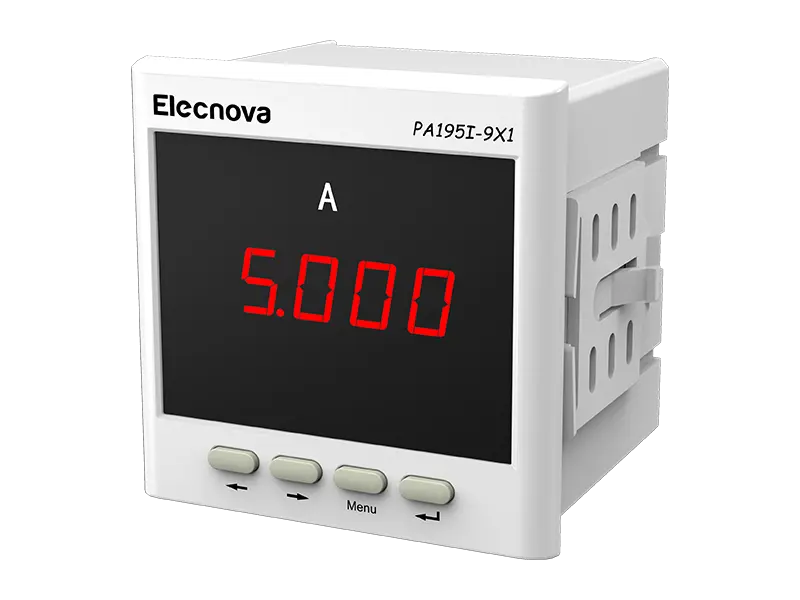

Man-machine interface

BCM201 HMI

Functional characteristics

Display data of incoming and feeder circuits, record fault information

Adopting a 7-inch human-machine interface.

The human-machine interface has alarm information prompts and audible alarms.

Parameters can be set between modules.

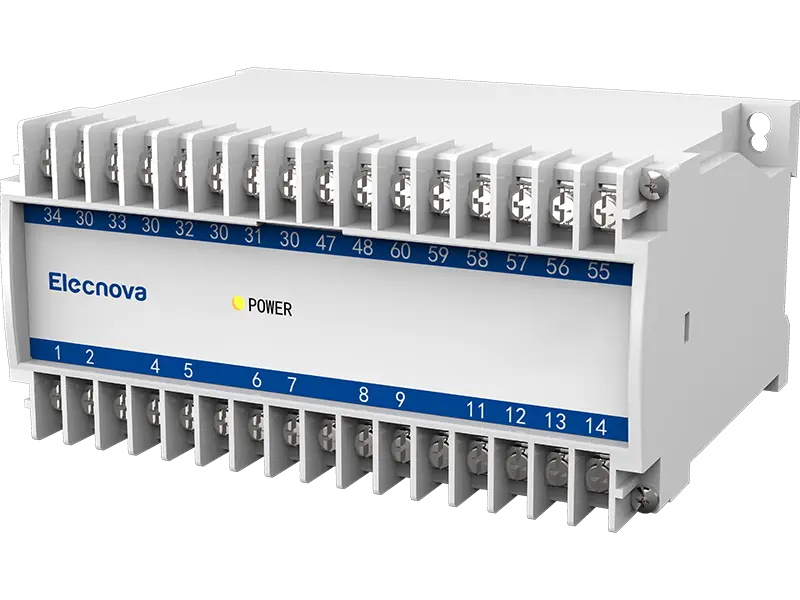

Incoming monitoring module

BCM201-M

Functional characteristics

Measure the grid parameters of two DC incoming circuits, including voltage, current, power, energy, demand, extreme values, temperature, and other parameters.

Equipped with 2 RS485 communication interfaces and optional Ethernet communication interfaces.

8 switch inputs and 2 relay outputs.

Having a record of multiple rate electricity consumption, storing energy for the past 10 years.

Has 1024 SOE event records, 1024 real-time alarm records, and 12800 alarm records.

Feeder monitoring module

BCM201-S

Functional characteristics

Measure the power grid parameters of 30 DC circuits, including voltage, current, power, energy, demand, extreme values, and other parameters.

30 switch inputs are used to determine the opening and closing of the circuit breaker based on the voltage value.

Equipped with 2 bus interfaces, the monitoring module can be expanded through the bus interface.

A bus can connect up to 3 BCM201-S feeder monitoring modules, monitoring 90 circuits.

Insulation monitoring module

BCM201-N

Functional characteristics

Measure the resistance values of two positive and negative busbars to ground.

When the insulation resistance of the positive and negative busbars is lower than the alarm threshold, an alarm message can be issued, and the branch inspection function can be activated to measure the positive and negative insulation resistance values of the branch to ground.

Multiple fault alarm functions: insulation resistance to ground, branch insulation resistance to ground fault, etc.

It can reflect the communication status of each branch in real-time, ensuring the stability and troubleshooting of the entire system.

Feeder switch quantity monitoring module

BCM201-K

Functional characteristics

It can simultaneously monitor the opening and closing status of 60 switches.

24V active wet contact connection.

Equipped with 2 bus interfaces and expandable monitoring modules.

A bus can connect up to 2 BCM201-K switch quantity monitoring modules.

![[Full Moon and Mid Autumn Festival Accompanied by Thick Feelings] Sfier Electric's Mid Autumn Festival Celebration Event [Full Moon and Mid Autumn Festival Accompanied by Thick Feelings] Sfier Electric's Mid Autumn Festival Celebration Event](/uploads/image/20240326/15/sfier-electrics-mid-autumn-festival-celebration-event.webp)