Throughout the years, countries around the world have paid high attention to energy security, environmental protection, sustainable development, and energy prices. It is expected that global energy consumption will soar by 40% in the next 25 years! Unless we can discover a huge coal mine, we cannot meet the current demand!

Faced with the intensification of the globalization epidemic, various industrialized enterprises can only choose to quickly face it: while tightening their belts globally, energy scarcity is no longer just a red headed issue.

Energy consumption and management costs continue to rise, and enterprises can only accelerate the construction of energy management systems, reasonably layout energy facility configurations and control functions, effectively improve facility and energy utilization efficiency, and reduce costs, in order to achieve better healthy and stable growth.

Szfel has been actively exploring technologies that can help optimize processes and remotely manage assets, such as in automotive manufacturing companies. Even for companies with similar products, production volumes, manufacturing processes, and geographical locations, due to differences in planning, design, and operational management, the energy consumption per unit product can differ by more than 50%.

The SFERE-EMS energy management system can help managers comprehensively grasp the energy consumption situation of enterprises, and decompose the energy consumption plan tasks of enterprises into various departments and workshops, tap into energy-saving potential, make energy-saving management more standardized and refined, and promote the healthy and stable development of enterprises.

Case analysis

A globally renowned automotive company has built a new production plant for key components of sedan engines and chassis. The products include camshafts, connecting rods, crankshafts, cylinder liners, front and rear steering knuckles, forks, and front and rear brake discs, mainly used for the production needs of domestic and overseas companies. The new plant covers an area of 134280 square meters.

At present, in the various production processes of automotive components in the factory area, energy mainly comes from electricity, water, gas, and compressed air. If manual meter reading is used to calculate the proportion and total amount of energy consumption, it will consume a lot of time and labor costs.

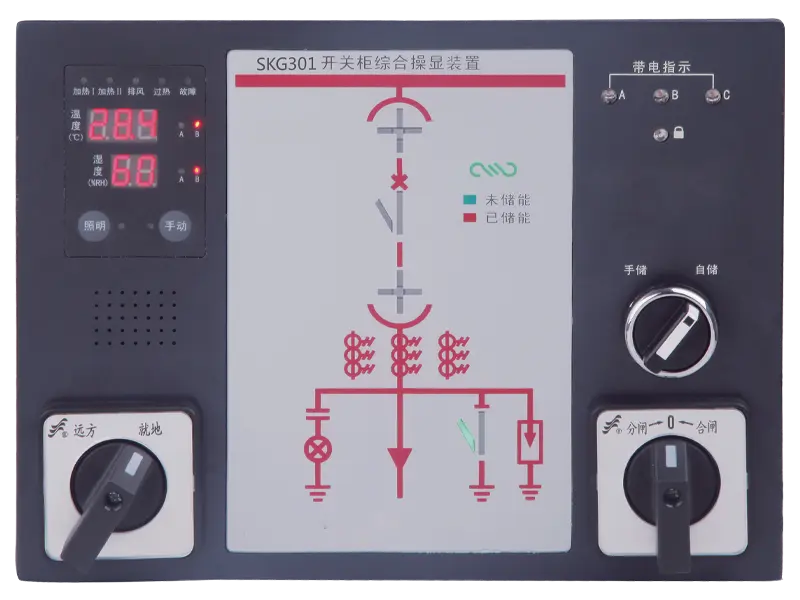

Schematic diagram of SFERE-EMS energy efficiency management platform

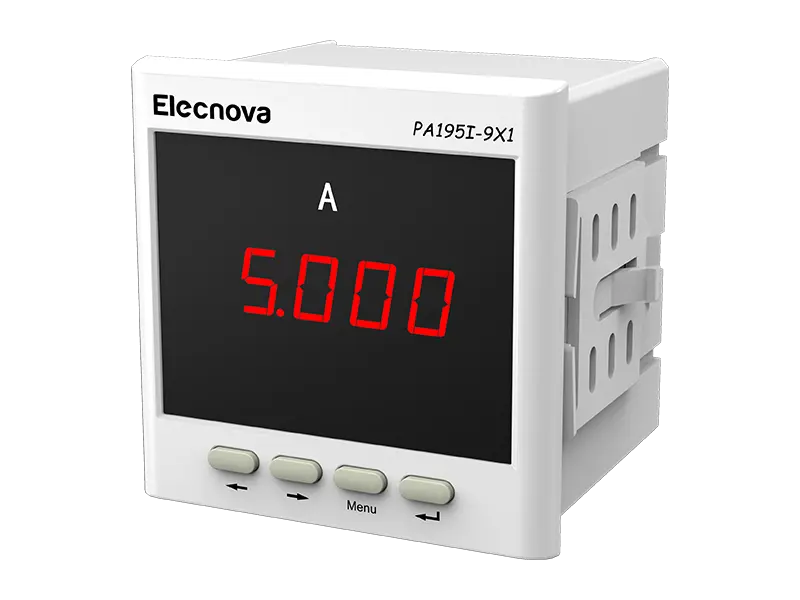

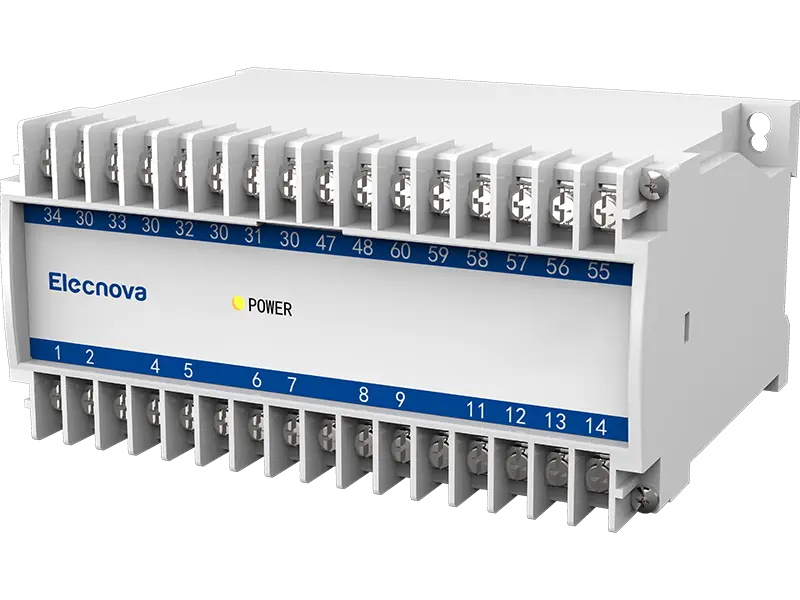

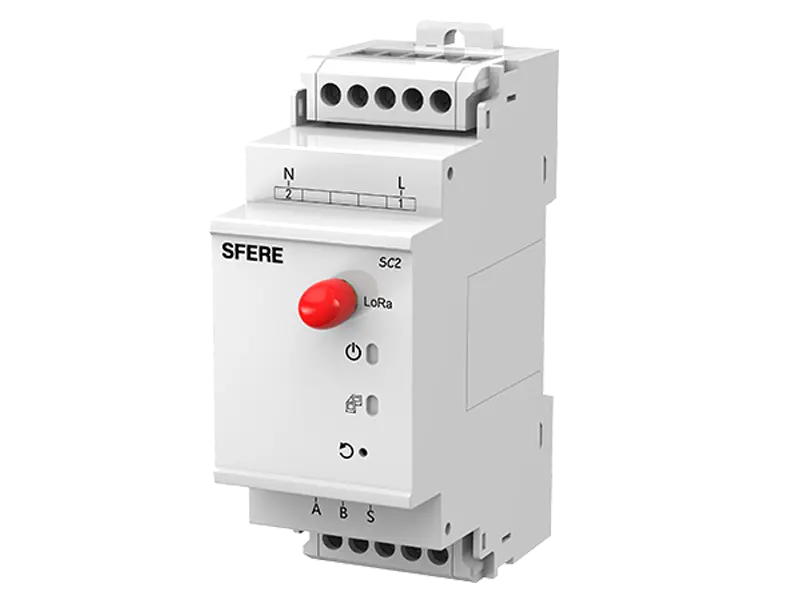

The measurement monitoring points in the factory area are distributed in various areas of the factory, as shown in the table below:

The EMS energy management system manages the electricity, water, gas, heat, oil and other energy sources of enterprise units, combined with other factors of the enterprise (production, cost, etc.), to make comprehensive data analysis and provide decision-makers with efficient and accurate data analysis; To deeply mine energy data for users, eliminate energy waste, and achieve energy-saving and emission reduction effects. The functions and significance of energy management systems go beyond that.

The functions and significance of energy management systems

Real time monitoring

Establish a company energy utilization plan. Implement statistical, comparative, and trend analysis of energy consumption data for all major secondary energy consuming units and major energy consuming equipment in the company based on time, energy types, measurement levels, etc. Establish a production energy control system that integrates data collection, process monitoring, and energy management through real-time monitoring of energy usage. Having an energy flow diagram that can intuitively and vividly summarize the overall picture of the enterprise's energy system, as well as a measurement network diagram that can describe various energy flows and the allocation of energy measuring instruments. Store at least 5 years of historical data and can be accessed at any time. The energy management system is integrated with MIS, OA systems, and other systems to achieve comprehensive energy management covering energy plan management, energy performance management, energy balance management, energy statistical analysis reports, and other functions. It provides accurate and effective analysis data to improve the energy management level of the entire company.

Energy consumption benchmarking management

Support manual import of production data; Real time online display of main product unit consumption, unit output energy consumption, and key equipment energy efficiency indicators; Realize dynamic benchmarking of product consumption indicators and key energy consuming equipment. By comparing and analyzing energy consumption indicators from multiple perspectives, comparing them with national standards, provincial and municipal standards, and enterprise standards, as well as comparing quotas and energy-saving targets. When there is a problem with benchmarking, find abnormal points (high or low), quickly analyze and judge the trend and cause of energy consumption changes, which is convenient for managers to tap into energy-saving potential and find the key to energy-saving management.

load management

Equipment load tracking and contract limit management, providing load declaration recommendations.

load control

Develop a comprehensive load control strategy based on the level of on-site energy consuming equipment, and write the strategy into the software self-control program. When extreme energy consumption occurs, the load control system prioritizes ensuring the use of safe load energy, followed by supplying important load energy, in order to maximize the safety of factory production.

Energy efficiency assessment

Conduct energy consumption assessment by conducting energy consumption statistics and analysis on major secondary energy consuming units.

Data entry

Improve the historical data structure through manual data entry.

Device management

By identifying information codes and manually entering energy consuming equipment information into the system, the system will automatically classify it and provide regular maintenance reminders based on the classification of energy consuming equipment. At the same time, provide comprehensive, timely, and accurate equipment information reports for energy management personnel in various professions during selected time periods, and be able to output and print them.

Key energy consuming equipment simulation

Simulate key energy consuming equipment such as melting furnaces and heat treatment equipment, and provide expert database opinions and reminders on potential hazards of key energy consuming equipment by comparing actual operating data. Timely warning and alarm for equipment energy consumption exceeding standards, low energy efficiency, and equipment failure prediction.

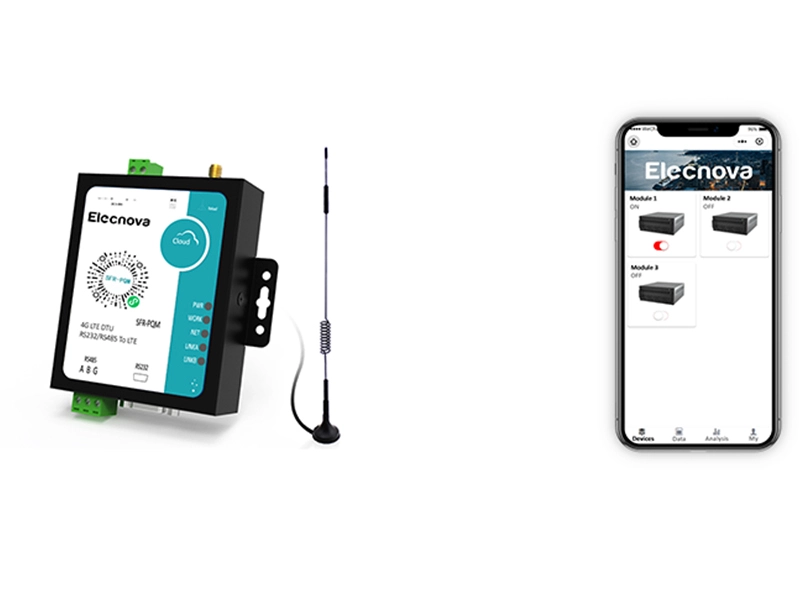

Mobile terminal applications

To facilitate the user's demand for real-time data monitoring, an application based on IOS and Android terminals is provided, which can display important monitoring data and warning and alarm information of the energy management system in real time on mobile terminals through internal networks or Internet networks.

Assisting decision-making

Provide real-time decision-making analysis and guidance for enterprise managers through comparative analysis of energy consumption data.

Alarm screen and expert plan system for early warning and disposal

Based on basic energy consumption data, establish a baseline. When the baseline is exceeded or significant fluctuations in energy consumption occur, timely alarm information can be issued, and the fault location can be displayed through the company's energy consumption plan, with a red alarm signal issued to improve the efficiency of event handling by management personnel.

Classification and sub item measurement

Energy supply and demand are measured step by step, and energy consumption comparison and assessment are flexibly specified for workshops, teams, and production lines as needed. Conduct multidimensional statistical analysis on enterprise energy consumption, tap into energy-saving potential, and truthfully and normatively submit energy statistical data.

Energy consumption system

Accurately record the energy consumption status of each link and equipment, decompose and analyze energy consumption data, and establish a key assessment index system to help managers timely grasp each link of industrial production, discover excessive consumption or waste of energy consumption in a timely manner, effectively promote energy-saving transformation work of enterprises, reduce production costs, and reduce the generation of pollution.

Unit energy consumption index

The energy management system is integrated with the production system, reading product data from the production system to calculate energy consumption per unit product output, energy consumption per 10000 yuan output value, energy consumption per unit building area, and energy consumption indicators for main processes. It is compared and analyzed with advanced international and domestic levels to systematically plan and implement energy management and control activities, incorporate energy-saving technology progress mechanisms into the energy management system, and strengthen energy management.

Scientific control and decision-making assistance

Using mathematical statistical methods to process energy consumption related data, design and draw various charts, and using input-output methods to macroscopically analyze energy utilization status. Through energy consumption reports, the completion status of energy consumption quotas, reasons for energy consumption and cost increase or decrease, their influencing factors, improvement measures, and energy-saving potential are displayed, providing high-quality decision support services for enterprise managers.

Energy indicator analysis module

The system provides comprehensive data aggregation, statistical analysis and other functions to identify energy consumption levels, achieve abnormal analysis of enterprise indicators, timely discover problems in the development process of enterprises, so as to facilitate timely solutions and fully tap into the energy-saving potential of enterprises. By collecting real-time data and conducting in-depth calculations, important energy consumption indicators of the enterprise are obtained. By comparing and analyzing with various constraint indicators, an optimization plan for the energy consumption situation of the enterprise is obtained. As an important component of enterprise automation and informatization, the EMS energy management system not only plays an important role in the unified scheduling of energy, optimizing resource balance, reducing coal and electricity emissions, improving environmental quality, reducing energy consumption, and improving labor productivity, but also is very effective in the formulation and execution of accident plans, rapid analysis and timely judgment of accident causes, reasonable adjustment and balance of energy supply and demand, and energy performance analysis based on objective information, energy planning, energy quality management, and energy system prediction.

Write at the end

With the intensive introduction of energy-saving laws, regulations, and policy standards, as well as the continuous increase in energy prices and costs, enterprises (especially key energy consuming enterprises) are paying more and more attention to energy-saving work. It is urgent to achieve the informatization, refinement, and systematization of energy management in order to improve energy performance, reduce energy consumption costs, and enhance market competitiveness.

With the support of national and local incentive policies, the energy management system, as an integrated energy control system that integrates automation, informatization, and centralized management modes, has received attention and recognition in multiple industries such as automobile manufacturing, steel, coal, cement, mobile telecommunications, schools, and construction. A large number of energy management systems have been built and put into use one after another.