Project Background

The integrated circuit chip manufacturing industry is a precision manufacturing industry with highly intensive capital and technology. Its production has significant characteristics. The production process requires high environmental cleanliness and strict requirements for temperature and humidity. In the production process, electronic devices and integrated circuits are used on a large scale and the degree of automation is relatively high, which requires high power supply quality.

The manufacturing of integrated circuit chips involves multiple key equipment, multiple workstation tools, and complex process steps. In addition to the power supply and distribution system, a transmission system, ultra pure water purification system, vacuum system, air-cooled air cooling system, and special gas distribution system are also required to ensure the smooth implementation of the production process and the safe operation of key equipment.

Due to the fact that the production conditions of the entire factory are ultimately achieved through electricity supply, semiconductor chip manufacturing has particularly high requirements for power supply quality. Design and integrate SFR-PQM power quality management platform based on the actual situation of semiconductor factories.

2SFR-PQM Power Quality Management Platform

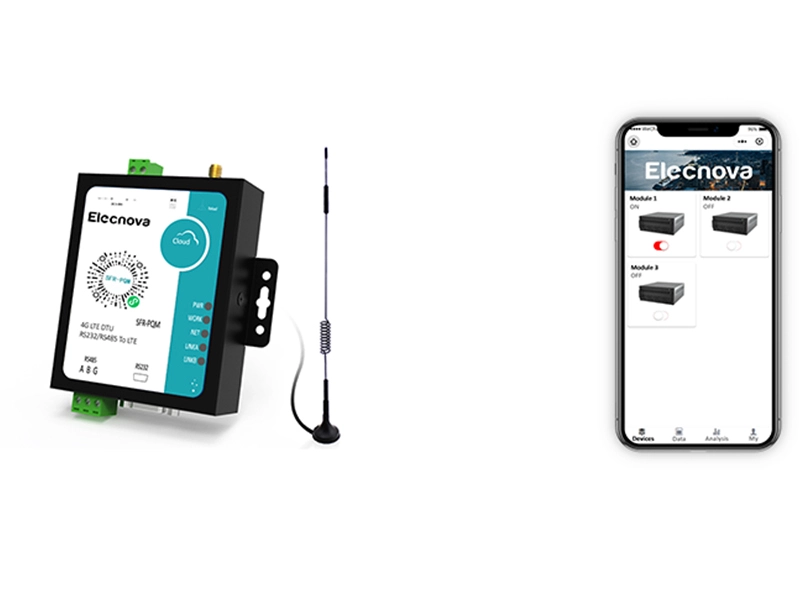

The Power Quality Management Platform (SFR-PQM) is a complete ecosystem formed by the integration of power quality products and equipment into the cloud.

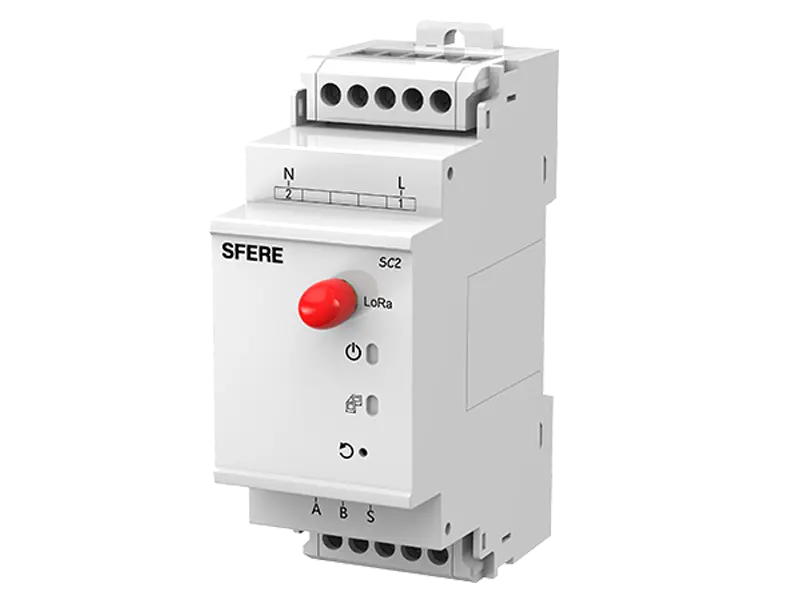

Through the platform, users can flexibly read various types of power equipment data, with high platform integration, effective data aggregation through multiple channels, support for 4G cellular network multi band coverage, RS232/RS485 and other communication interfaces, meeting various methods of data collection; Adopting high-performance industrial grade wireless modules, supporting an extremely wide temperature design of -35 ° C to+75 ° C, easily adapting to high temperature and cold working environments, providing reliable networking and stable communication for unmanned systems.

Product Advantages

Easy to operate

Through the WeChat mini program, there is no need to install an app, the operation is simple, and the interaction is convenient.

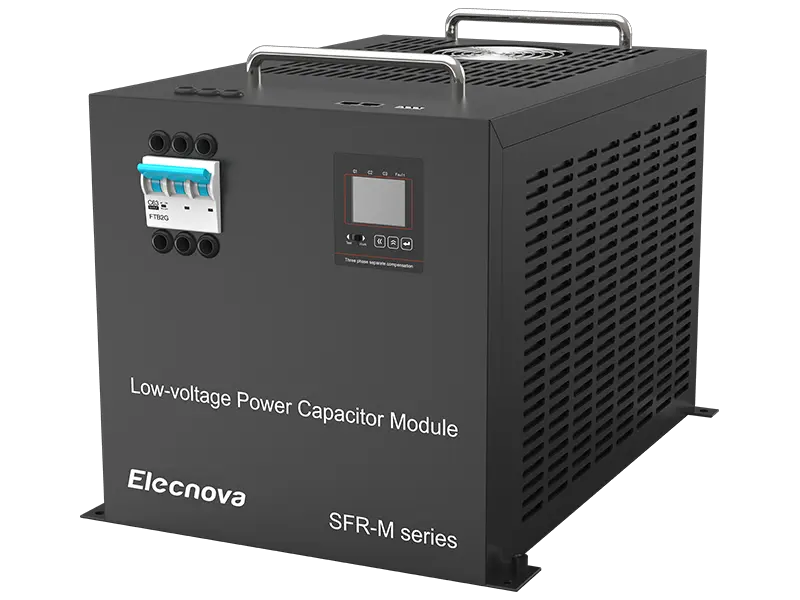

accessory products

Supporting the company's active filter cabinet, static reactive power generation cabinet, and intelligent reactive power compensation cabinet.

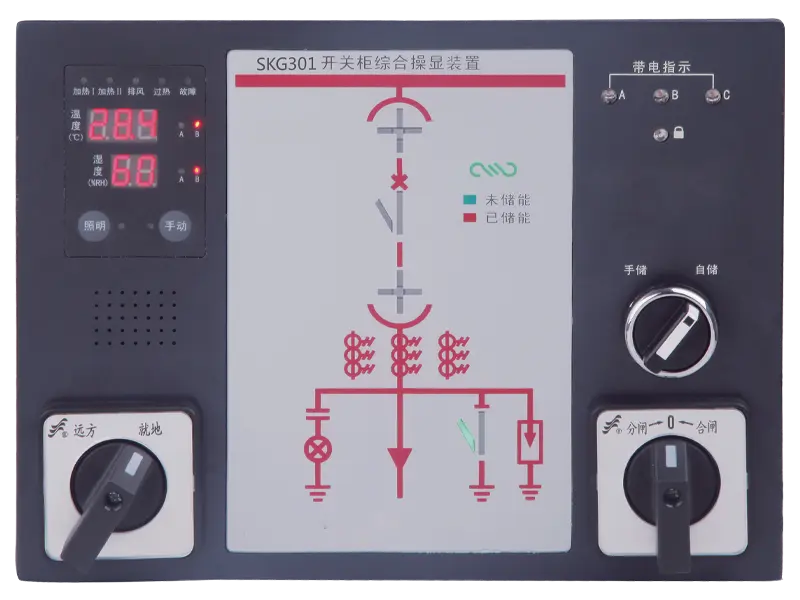

Visual display

The graphical interface intuitively displays various electrical energy data inside the cabinet and analyzes the harmonics and power factor of the distribution system, and provides a switch operation interface.

Quick distribution network

The data of the power quality cabinet is automatically added when connected to the network, without the need for manual addition.

Remote control

Centralized monitoring, configuration, upgrading, diagnosis, maintenance, and control of a large number of scattered equipment in various regions. Greatly reduce maintenance costs for operators, integrators, equipment providers, and other parties, and improve management efficiency.

Recommended Products

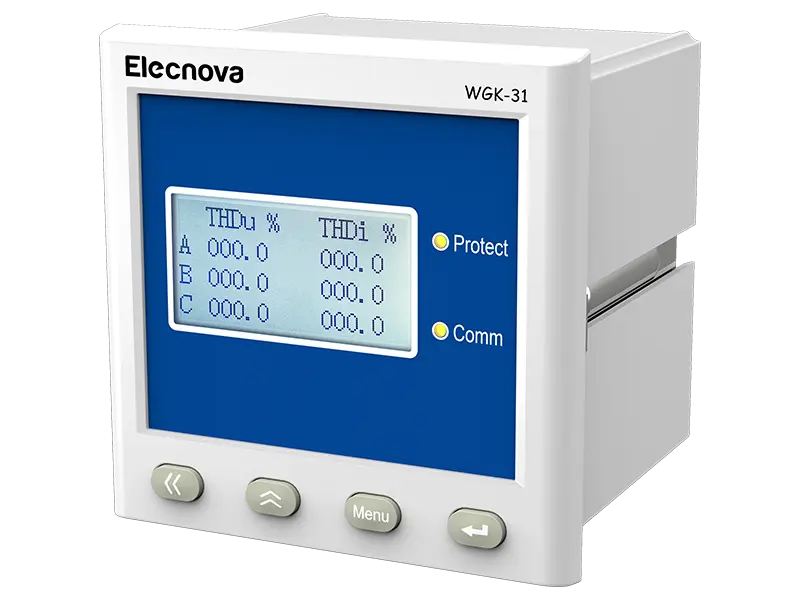

WGK -31-700 reactive power compensation control terminal

The reactive power compensation control terminal is a set of equipment specifically designed for correcting power factor and compensating reactive power, with the function of automatic detection and control of reactive power. By using advanced visual analysis and calculation tools, combined with advanced power quality monitoring instruments, professional control and management of power quality can be achieved.

Product advantages

Real time monitoring and control of dynamic user interfaces, combining real-time display and control functions to achieve more effective control and higher operational efficiency.

harmonic analysis

Realize the analysis of 2nd to 31st harmonic data through graphics and tables.

Safe and stable

Fault tolerance is achieved through software architecture redundancy, network redundancy, and communication redundancy to ensure data reliability. Monitor power factor fluctuations within the set time range and compare power factors before and after compensation.

Alarm triggered

Alarm triggering based on specific conditions, with independent screen alarm prompts recording events and all related data in sequence.

Scalable

21 level control outputs or intelligent capacitor networking control are available.

Operation and maintenance management

Reminder for capacitor module replacement, calculation of remaining capacity and cumulative operating time, providing first-hand equipment data for on-site maintenance personnel to ensure safe operation of reactive power compensation.

Write at the end

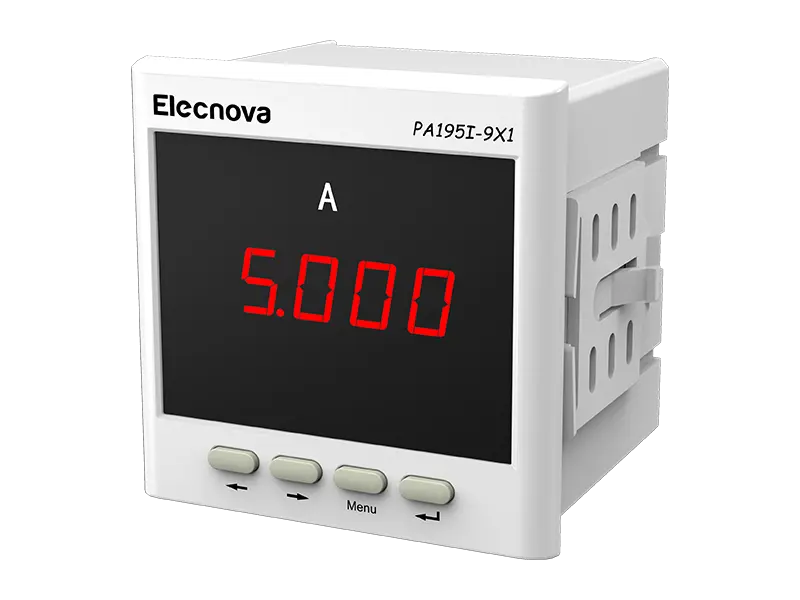

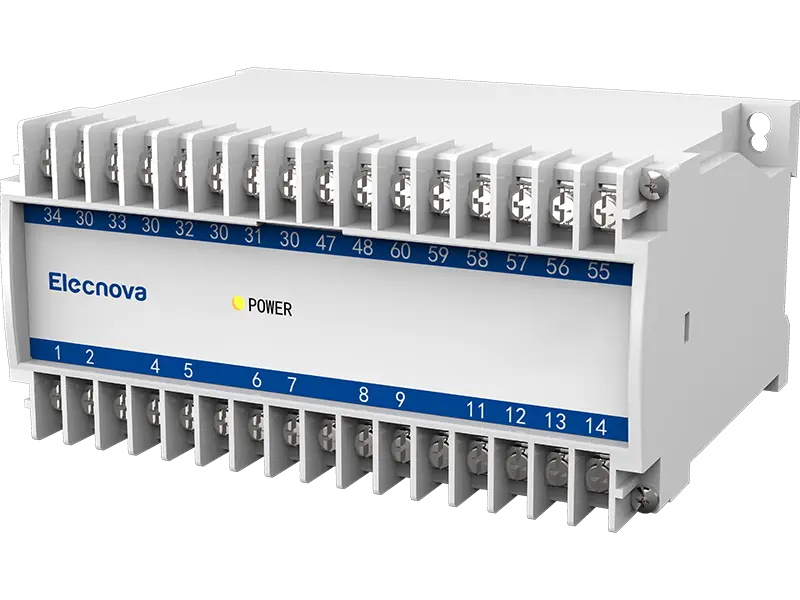

WGK-31-700 integrates multifunctional meters, reactive power compensation controllers, and ammeters. WGK-31-700 is not only a functional integration, but also a systematic data processing, providing customers with more intuitive and comprehensive operation and maintenance management information, achieving a "1+1+1>3" effect. WGK-31-700+SFR-PQM is generally used in combination, including reactive power compensation control terminals, 4G modules, and application programs. We will soon carry out modular expansion of the reactive power compensation control terminal and integrate it into the power quality management platform, forming a set of application solutions from offline to online, and from local to remote.